Overview

A Baggage Handling System (BHS) is a conveyor system installed in airports that transports checked and booked luggage from check-in ticket counters to areas where the bags can be loaded onto airplanes. A BHS also transports arrived checked baggage coming from airplanes to baggage reclaims carousels.

BHS perform the following main functions:

- Transport luggage from ticket counter to the make-up carousel

- Transport and inject luggage on the reclaim carousels

- Detection of bag jams through sensors and CCTV cameras

- Bag counting

- Bag tracking

- Redirection of bags via pusher or diverter

- Automatic Tag Reader (ATR) to read the tags on the luggage provided by the airlines

There is an entire process that the BHS controls automatically through automation and instrumentation. From the moment the bag is set on the inbound/outbound conveyor, to the gathering conveyor, through sorting until it arrives at the designated aircraft or onto the baggage makeup carousel after the flight.

All the automation is controlled by SCADA, PLCs and Sort Allocation Computers (SAC) installed in the control rooms.

Our Expertise

Acrux Technologies has the ability to provide installation, operations and maintenance (O&M) of complete Baggage Handling Solution. The technical team of Acrux is qualified and trained to offer reliable and efficient O&M support to following components of BHS:

- Upstream conveyors, diverters and all the other components

- Make-up and reclaim carousels

- ATR (Automatic Tag Reader)

- Integration with HBS (Hold Baggage Screening)

- Control systems (SAC and SCADA)

- Baggage Information Display System (BIDS)

- Integration with Airport IT

Main Components of BHS

BHS includes different baggage handling products:

- Check-in belts with scales

- Conveyors

- Sequencers/metering

- Confluence/Injection

- Curves

- Vertical and horizontal diverters

- Fire and Security Shutters

Make-Up and Reclaim Carousels

Overlapping flaps carousels, flat and inclined, are parts of the baggage handling system. These carousels can be configured with stainless steel or painted steel body and are suitable for the use at the make-up, in departure sorting systems, or at the baggage reclaim in the arrival halls.

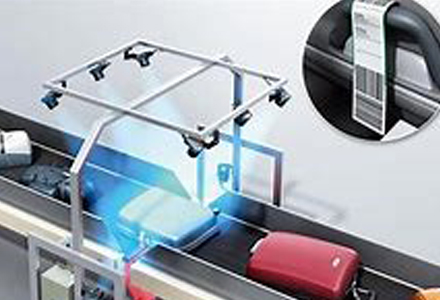

ATR (Automatic Tag Reader)

BHS includes advanced products for the automatic reading of the baggage tags using standard barcode readers, Barcode cameras are installed on different positions and orientations so that a tag on luggage can be read irrespective of bag position on conveyors.

Integration with HBS (Hold Baggage Screening)

The security of air transport being the top priority of all the airport authorities and airlines, BHS solution integrates with the latest generation baggage screening machines (Standard 3).

The layout design of the baggage handling systems always keeps into account both the requirements for the security related “waiting times” and the need for a fast flow of the “clean” baggage to achieve the highest possible throughput with the maximum security level.

Control Systems (SAC and SCADA)

Baggage Handling System is linked with the main control systems to provide a full turnkey solution:

- SCADA, for the command and control of all the single devices and the entire plant;

- SAC (Sorting Allocation Computer) for the management of the sorting and the complete tracking of the baggage

Integration with Airport IT

All the control systems and the Baggage Reconciliation System are integrated with the IT systems of the airport information technology infrastructure. The standard set of messages defined in the IATA recommendations are implemented.

The SCADA is also integrated with global airport monitoring systems through standard protocols.